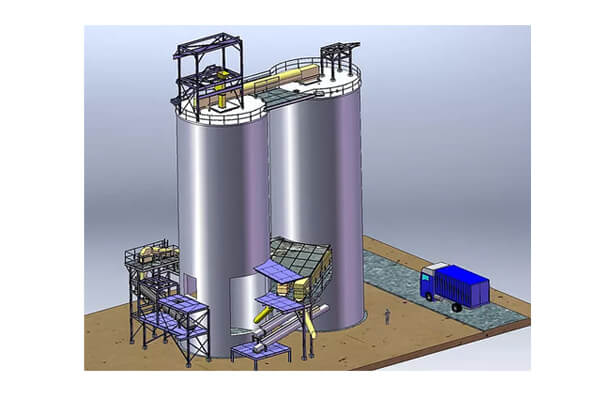

Koenig Blending Silos

Koenig offers 2 types of Blending cum Storage and extraction system. Our Blending silos are continuous feed and gravity blending type. The blending is achieved through sequential aeration and extraction methods which stimulates the variable material velocity inside the silo and thus blending / mixing happens by gravity. This is no energy spend for blending and blowers are used only to aerate the material for extraction and NOT for blending.

Aeration air is supplied through a set of dedicated Positive Displacement Blowers and the Standard accessories include Over / Under pressure relief valve, man hole doors.

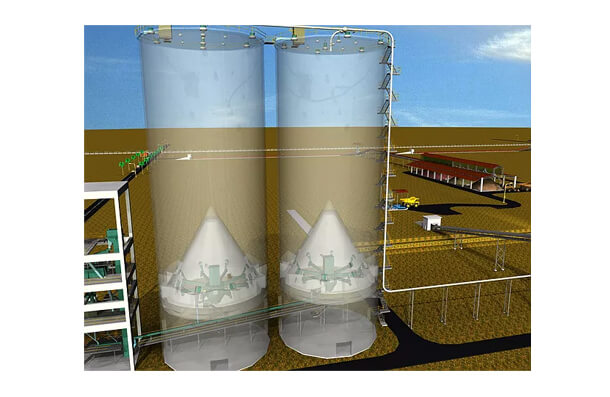

Inverted Cone Blending Silos

This type of silos are the most efficient blending silos as we can increase the No. of extraction to meet the expected blending requirement. To avoid segregation of coarse particles, silo is fed through multiple points sequentially.

The inverted central cone is used to accommodate the necessary machinery and equipment such as Aeration fan, blowers, filters, electric control cubicle, and all silo extraction gate system.

Each outlet is provided with Koenig Manual Slide gate followed by Koenig Flow control valve and Koenig PneuSlide system to feed to the Koenig Bin weighing system.

- Standard Silo sizes are ⌀14m, ⌀16m, ⌀18m, ⌀20m, ⌀22m.

- Special sizes and configurations on request.

Flat Bottom Blending Silos

Koenig also offers Flat Bottom blending silos by dividing the silo internal aeration with multiple segments. We have three types of Flat Bottom Blending silos with 24 Segments, 36 Segments and 42 Segments respectively. No. of segments determines the blending efficiency.

Flat Bottom Blending silos can be constructed with limited civil construction capabilities. The complete inside surface of the bottom slab is mounted with Koenig Aeration pads and the withdrawal from Silo center. To reduce the load on extraction gates and avoid possible bridge formation, a steel cone is mounted at the extraction location at center. The main advantage of Flat Bottom Blending Silo is less number of extraction gates and thereby less maintenance.

The central outlet is provided with Koenig Manual Slide gate for maintenance followed by aerated junction box, Koenig Flow control valve and Pneuslide system to feed to the Koenig Bin weighing system.

- Standard Silo sizes are ⌀14m, ⌀16m, ⌀18m, ⌀20m, ⌀22m.

- Special sizes and configurations on request.